Taibong Plate Heat Exchanger Catalogue

Manufacturer: Taibong

Origin: South Korea

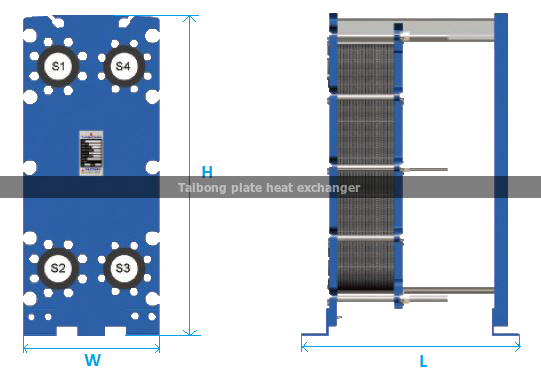

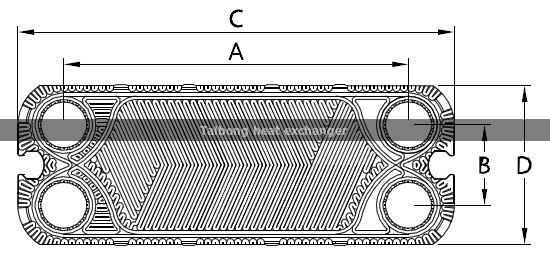

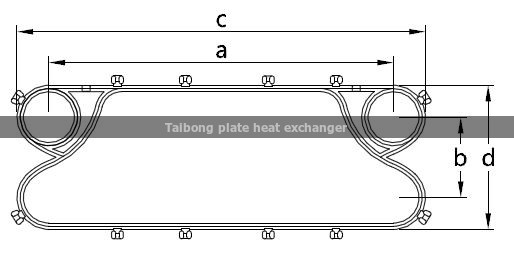

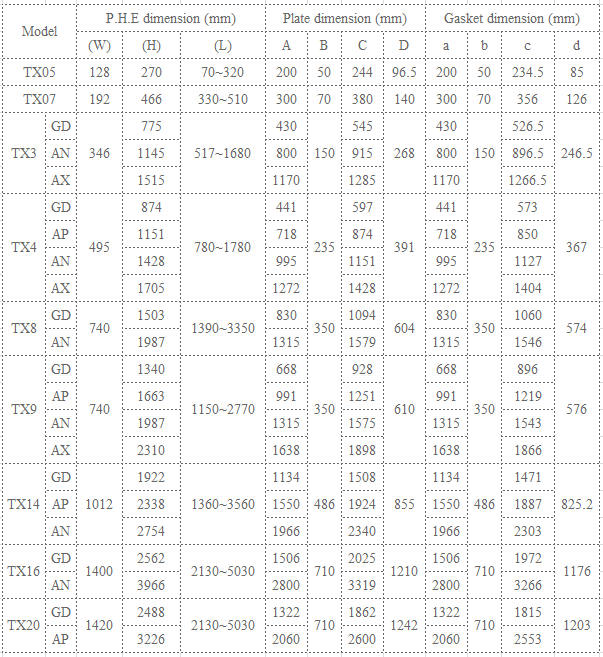

1. Specifications of Taibong Plate Heat Exchanger

2. Material of Taibong Plate Heat Exchanger

| Plate | SS304, SS316, SS316L, SMO254, SLX904, Titanium, Titanium-Palladium, Nickel, Nickel Alloy, Hastelloy-C, Etc. |

| Gasket Material | NBR, EPDM, HNBR, Viton, Teflon, Silicon |

| Max. Design Pressure | 34kg/cm2 |

| Max. Design Temperature | -30℃ ~ 210℃ |

| Hiệu suất trao đổi nhiệt | Có thể thay đổi công suất |

| Lợi ích | Nhỏ gọn, giá thành rẻ, dễ bảo dưỡng, đa ứng dụng |

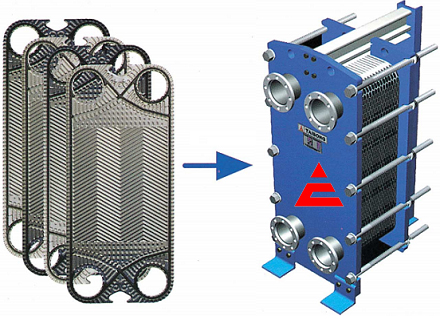

3. Structure

The plate heat exchanger is a device made up of multiple thin heat exchange plates stacked together. These heat exchange plates are assembled to form flow channels between the plates.

Rubber gaskets are placed between the heat exchange plates to seal and direct the flow. The heat exchange plates are positioned between two steel frames and are tightened with bolts, creating two counterflow paths that result in a high heat transfer coefficient.

4. Advantages

Heat exchangers come in various forms. Among them, plate heat exchangers (PHE) are commonly used due to their many advantages, including:

1. High heat transfer efficiency: Plate heat exchangers can transfer heat efficiently, achieving heat transfer rates between 85% and 90%. They are particularly suitable for heat exchange processes between two liquids.

2. Flexible adjustability: The heat transfer surface area of a PHE can be adjusted by adding or removing heat exchange plates. A heat exchanger can be divided into multiple chambers to simultaneously cool or heat fluids.

3. Compact design and easy maintenance: Plate heat exchangers have a compact structure that is easy to assemble, disassemble, clean, and maintain. These devices also occupy less maintenance space and are less likely to become clogged due to the high turbulence flow, making it harder for dirt to accumulate.

4. Low cost: PHEs are less expensive compared to other types of heat exchangers.

5. High heat transfer performance: Plate heat exchangers offer a higher heat transfer performance than shell-and-tube or spiral heat exchangers.

6. Smaller size: Compared to shell-and-tube heat exchangers, plate heat exchangers are 3 to 5 times smaller in size, yet they provide similar performance and capacity due to the high thermal transfer value and compact design of the heat exchange plates.

7. Good temperature control: PHEs have excellent temperature control capabilities and perform well with temperature differences between the two fluids.

5. How to Choose the Suitable Plate Heat Exchanger

To select the appropriate PHE, you can refer to the following factors:

1. Heat Capacity: Determine the required heat capacity based on the production process requirements to choose a device with the corresponding heat transfer capacity. Heat capacity is usually measured in Km or Kcal/h.

2. Fluid Characteristics: Consider the viscosity, pressure, and temperature of the fluid to select the appropriate material and structure of the heat exchange plates, ensuring efficiency and durability.

3. Heat Transfer Area: Calculate the necessary heat transfer area to achieve optimal performance. The heat transfer area can be adjusted by adding or removing heat exchange plates.

4. Size and Installation Space: Choose equipment with a size that fits the installation space, ensuring easy maintenance and cleaning.

5. Construction Materials: Select materials that can withstand specific operating conditions such as high temperatures, corrosion, and high pressure.

6. Brand and Supplier: Choose equipment from reputable suppliers to ensure quality and good technical support. Taibong heat exchangers are widely used in Vietnam.

7. Cost: Consider the initial investment cost and operational costs to choose equipment with high economic efficiency.

Clients can also refer to the product lines from the Taibong brand, South Korea, exclusively distributed by Titania, including: TX3GD, TX3AN, TX3AX, TX4GD, TX4AN, TX4AP, TX4AX. These are the plate heat exchanger models that are most favored and commonly chosen by Titania’s customers and partners.

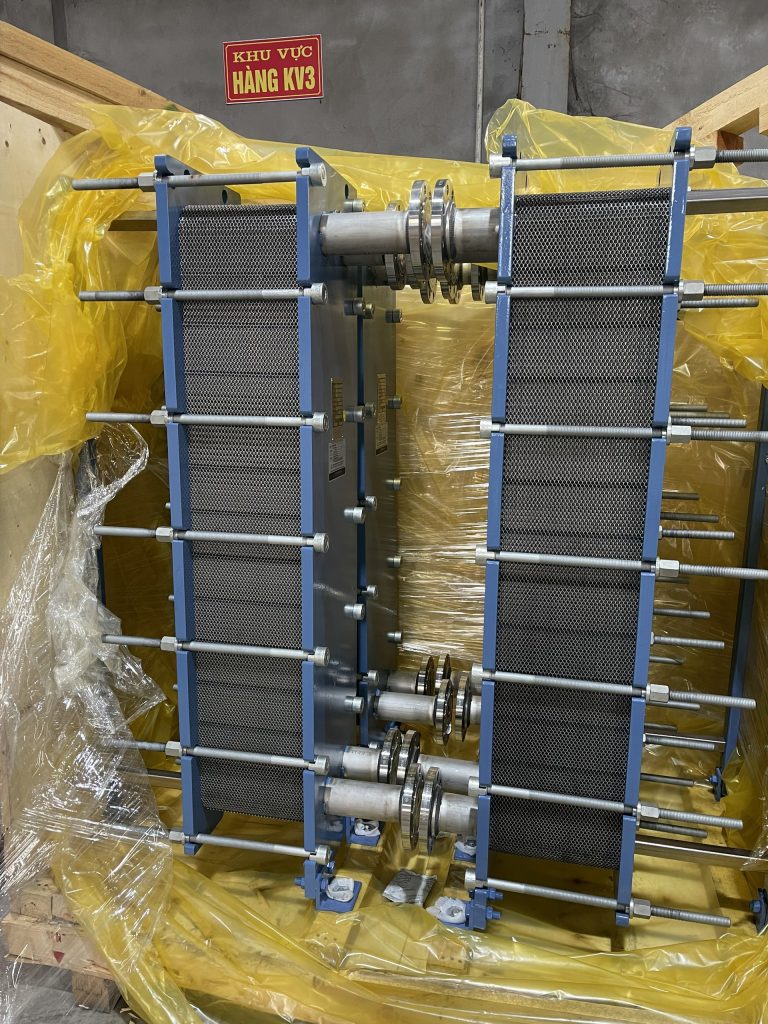

Here are some images of the Taibong plate heat exchangers installed in Vietnam

———————————————————–

Where to Buy Taibong Heat Exchangers

Titania Engineering Co., Ltd.

Hanoi Office: 162 Khuat Duy Tien, Thanh Xuan, Hanoi, Vietnam.

Hai Phong Factory: Nam Thuong Village, Thanh Dong Ward, Hai Phong City, Vietnam.

Tel: (+84) 2203-898-258 / Hotline: (+84) 931-576-258

Email: saledept@titania.com.vn / overseas@taibong.com