Spiral Heat Exchanger Manufacturer: Taibong

Origin: South Korea

1. Construction of Taibong Spiral Plate Heat Exchanger (SPHE)

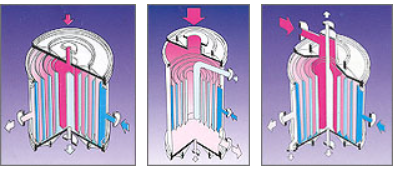

The Spiral Plate Heat Exchanger (SPHE) is a heat exchange device designed to optimize heat transfer efficiency. It consists of two metal plates that are joined together, running parallel in a spiral coil inside a shell. SPHE is used to transfer heat between two liquids, typically with high viscosity.

2. Technical Specifications

– Material of Heat Exchange Plates: Carbon Steel, Stainless Steel, Hastelloy, Titanium, Incoloy, Nickel.

– SPHE is designed for applications with high LMTD (Log Mean Temperature Difference) designs, high viscosity, and minimal fouling.

– Maximum Design Pressure: 18 Kg/cm².

– Maximum Design Temperature: 400°C.

– Heat Transfer Area: Varied, available in sizes such as 5, 10, 15, and more m².

3. Applications of Spiral Plate Heat Exchanger (SPHE)

The SPHE is a type of heat exchanger used to transfer heat between two liquids or gases:

– Evaporation and Condensation (gas – air, gas – liquid)

– Cooling and Heating (liquid – liquid, liquid – air)

The applications of the SPHE are diverse and widely used in industries such as oil and gas, chemicals, food and beverages, paper and pulp production, and other industrial sectors.

- Some specific applications of the Spiral Plate Heat Exchanger (SPHE) include:

– Heat Exchange in Oil and Gas Production: The spiral heat exchanger is used to transfer heat between liquids during the extraction, transportation, and refining of oil and gas.

– Food and Beverage Production: SPHE is used for cooking, cleaning, flavor enhancement, and preservation of food and beverages. Spiral heat exchangers are used to heat frying oil in snack and instant noodle production plants.

– Paper and Pulp Production: Spiral heat exchangers are employed to separate and recover heat in the paper and pulp manufacturing process.

– Other Industries: SPHE is also used in various other industries, such as pharmaceutical production, detergents, cosmetics, and personal care products.

4. Advantages

The spiral plate heat exchanger offers several advantages when used, including:

– High Heat Transfer Efficiency: The SPHE has a large heat transfer surface area, allowing for more efficient heat transfer compared to other heat exchangers.

– Flexibility: Spiral plate heat exchangers can be used for heat exchange between two liquids or between a liquid and gas. Additionally, they can be used in various applications, from industrial to specialized purposes.

– Self-Cleaning Capability: This type of exchanger has the ability to self-clean, with a low fouling coefficient.

– Energy and Space Savings: The compact design of the SPHE helps save both energy and space in heat exchange systems.

– Low Cost: Compared to other heat exchangers, spiral heat exchangers are more cost-effective, helping to reduce initial investment and operational costs.

Where to Buy Taibong Heat Exchanger

Titania Engineering Co., Ltd.

Hanoi Office: 162 Khuat Duy Tien, Thanh Xuan, Hanoi, Vietnam.

Hai Phong Factory: Thon Nam Thuong, Thanh Dong Ward, Hai Phong City, Vietnam.

Tel: (+84) 2203-898-258 / Hotline: (+84) 931-576-258