Taibong Shell and Plate Heat Exchanger

Manufacturer: Taibong

Origin: South Korea

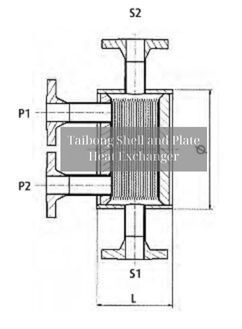

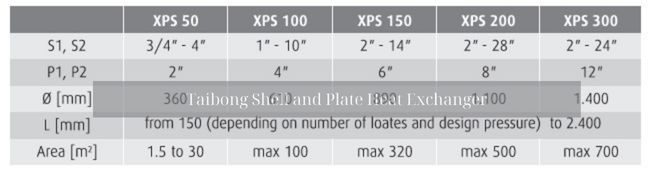

1. Specifications of Taibong Shell-and-Plate Heat Exchanger

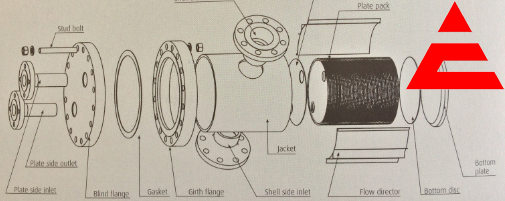

2. Structure

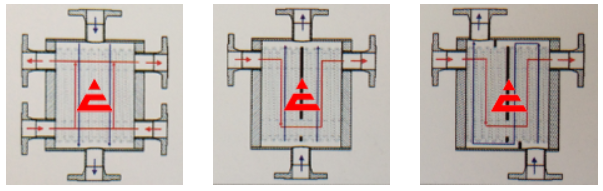

The Shell and Plate Heat Exchanger (SPHE) is a type of heat exchanger used to transfer heat between two fluids with different temperatures, through plates arranged inside a shell. The two fluids flow in opposite directions and transfer heat through thin plates. Each plate is embossed in various patterns to maximize heat exchange efficiency. Since the plates are sealed by welding and placed within the shell, the device is capable of withstanding high temperatures and pressures.

3. Technical Specifications

– Maximum Design Pressure: 150 Bar(g)

– Maximum Operating Temperature: -200℃ ~ 500℃

– Heat Transfer Area: 0.5 ~ 300 m²

– Materials: Stainless Steel, Nickel, Titanium, etc.

4. Advantages of Taibong SPHE

The SPHE by Taibong offers several advantages, making it a popular choice in various industrial applications:

- High Heat Transfer Efficiency: The SPHE is designed to maximize the heat transfer area and reduce fouling, which results in more efficient heat transfer compared to many other types of heat exchangers that deal with temperature changes.

- High Durability: SPHE is made from materials that can withstand high pressure, corrosion, and elevated temperatures, ensuring a long lifespan.

- Ease of Maintenance and Repair: This type of heat exchanger is designed for easy disassembly, cleaning, and replacement, reducing maintenance and repair costs.

- Flexible Design: It can be designed to meet various heat transfer requirements and purposes, making it adaptable to different applications.

- High Pressure Resistance: It can handle high pressures, making it suitable for use in high-performance applications that involve high temperatures.

- Space Saving: SPHE is compact in size and can be installed in limited spaces, helping save space in applications with space constraints.

5. Applications of Taibong Shell and Plate Heat Exchanger

The Shell and Plate Heat Exchanger is highly versatile and can be used in various operating conditions, from vacuum to ultra-high pressure, and from extremely low to extremely high temperatures. This equipment can handle different flow mediums with varying temperatures and pressures, both inside and outside the shell. Some common applications of the shell and plate heat exchanger include:

– Cooling and Refrigeration

– Condensation

– Heat exchange between liquid-liquid, vapor-liquid, gas-liquid

– Heat recovery

– Evaporation

– Heating

Primary Industries of Application:

Petrochemical

Oil and Gas

Power Generation

Metallurgy

HVAC Systems

Biotechnology

Marine

Food & Beverage

Some Real-World Images of Shell and Plate Heat Exchangers at Titania

Here are some real-world images of the Shell and Plate Heat Exchangers provided and installed by Titania in Vietnam:

Where to Purchase Taibong Shell and Plate Heat Exchanger

Titania Engineering Co., Ltd.

Hanoi Office: 162 Khuat Duy Tien, Thanh Xuan, Hanoi, Vietnam.

Hai Duong Factory: Thon Nam Thuong, An Thuong Commune, Hai Duong City, Vietnam.

Tel: (+84) 2203-898-258 / Hotline: (+84) 931-576-258