Plastic Heat Exchanger Catalogue

Manufacturer: Calorplast

Origin: Germany

The all-plastic heat exchanger is a device used for heat exchange between two liquids or gases. With a design made from plastic or polymer materials, it is commonly used in applications with low temperature and pressure, but with the ability to withstand chemical corrosion. This device is typically immersed in the fluid, which is why it is also known as an immersion heat exchanger.

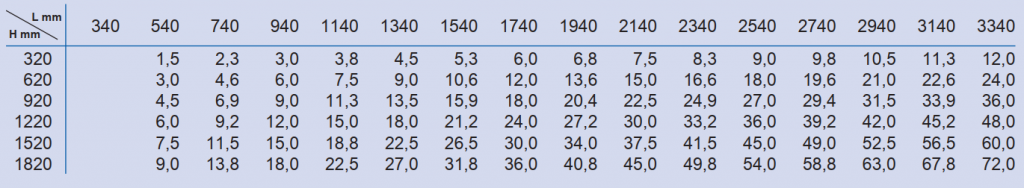

1. Specifications of Plastic Heat Exchanger

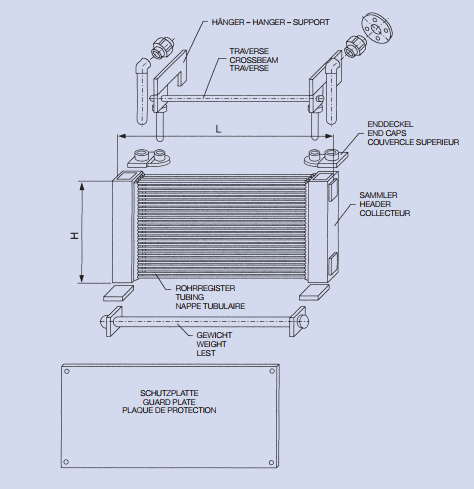

L: The length of the heat exchanger.

H: The height of the heat exchanger.

Materials: PE, PP, PVDF, PFA

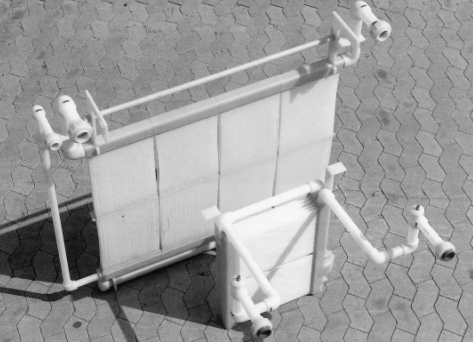

2. Structure of the plastic heat exchanger

– Shape: Can be in the form of tubes or plates.

– Heat transfer types: Gas – water; Gas – gas.

– The configuration of the plastic heat exchanger consists of thin plastic plates, welded at the ends, stacked and tightly bonded together. Each plastic plate has several holes at both ends to allow the fluid to flow in and out of the device. These plastic plates are designed to create channels for the fluid to flow through, facilitating heat exchange.

– When the fluid enters the plastic heat exchanger, it is directed through the heat exchange channels and comes into contact with the plastic plates. At the same time, another fluid flows through different channels of the device and comes into contact with other plastic plates. This process facilitates heat transfer between the two fluid streams, helping to either heat or cool one fluid with another.

– Maximum pressure: 16 bar

– Maximum temperature: 135°C (depending on the material)

– Maximum pressure loss: 0.5 kg/cm²

3. Advantages

– High durability: Made from high-quality engineering plastics, these devices can withstand high pressure and temperature, offering higher durability compared to those made from other materials.

– Corrosion resistance: The plastics used are typically resistant to corrosion, allowing the heat exchangers to be used in environments with high salt and acid content without being affected by corrosion.

– Quick operation and easy maintenance: These devices are typically designed with simplicity, making them easy to operate and maintain. They do not require many tools or technical skills for maintenance or repair activities.

– High flexibility: Plastic heat exchangers can be produced in various sizes and shapes, making them suitable for a wide range of applications in industrial settings.

– High-temperature stability: The plastics used have good heat resistance, capable of withstanding temperatures up to 120°C, making them suitable for high-temperature applications.

4. Applications of Plastic Heat Exchanger (Immersion Heat Exchanger)

This device can be used in various applications, but it is most commonly found in air conditioning systems, industrial cooling, food production and processing, and medical applications.

Specifically, some specific applications include:

– Air conditioning systems in buildings and high-rise buildings: This device is used to transfer heat between outgoing and incoming air, helping save energy and reduce costs.

– Cooling equipment in food production and processing: The plastic heat exchanger is used to cool machinery, equipment, or production processes in food factories, breweries, and beverage factories.

– Medical applications: It is used in medical devices such as oxygen concentrators and dialysis machines to transfer heat between the coolant and air.

However, to select the appropriate heat exchanger for a specific application, it is essential to thoroughly understand the properties of the fluid or gas being heat transferred, pressure, temperature, and technical requirements of the system. For more detailed information about the product and to choose the right one for your intended use, please contact us directly for free consultation.

Address to purchase plastic heat exchanger

Titania Engineering Co., Ltd.

Hanoi Office: 162 Khuat Duy Tien, Thanh Xuan, Hanoi, Vietnam.

Hai Duong Factory: Nam Thuong Village, An Thuong Commune, Hai Duong City, Vietnam.

Tel: (+84) 2203-898-258 / Hotline: (+84) 931-576-258

Email: saledept@titania.com.vn